The fermentation is carried out in a closed space, so the heat loss is low and the efficiency is high. There’s no need to add subsidiary materials or bacteria during the production process.

The fermentation is carried out in a closed space, so the heat loss is low and the efficiency is high. There’s no need to add subsidiary materials or bacteria during the production process.

No waste water discharge, and no secondary pollution.

No waste water discharge, and no secondary pollution.

Exhaust gas is collected and treated in a centralized manner which meets strict environmental protection requirements.

Exhaust gas is collected and treated in a centralized manner which meets strict environmental protection requirements.

The continuous high temperature generated during fermentation can kill pathogenic bacteria, weed seeds, etc.

The continuous high temperature generated during fermentation can kill pathogenic bacteria, weed seeds, etc.

Less land occupy, high degree of automation, easy to operate and labor-saving.

Less land occupy, high degree of automation, easy to operate and labor-saving.

The livestock and poultry manure can be directly converted into high-quality organic fertilizer which can be used on farms directly.

The livestock and poultry manure can be directly converted into high-quality organic fertilizer which can be used on farms directly.

Ask Now

Ask Now

Item

Effective volume of fermentation tank

Diameter * Total Height

Weight

Daily treat capacity: when the water content of pig manure is 78%

Daily output of organic fertilizer

Daily treat capacity: when the water content of chicken manure is 65%,

Daily output of organic fertilizer

Installed Power

Parameter

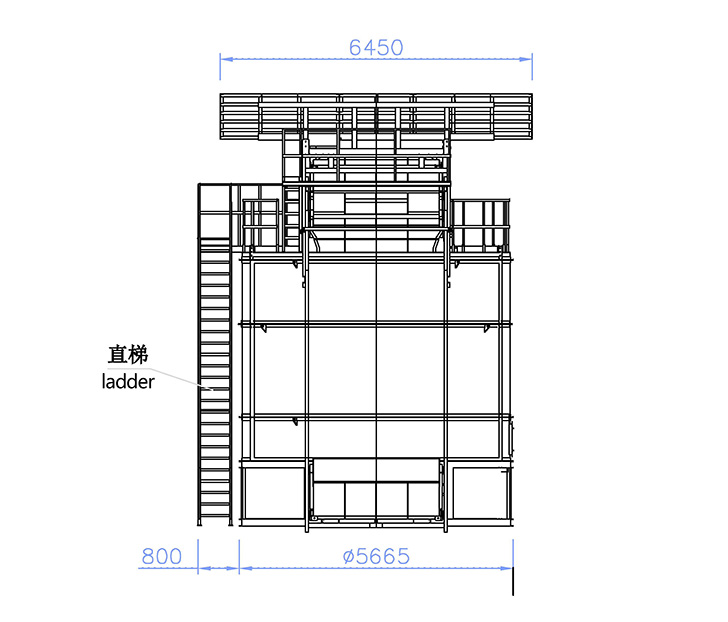

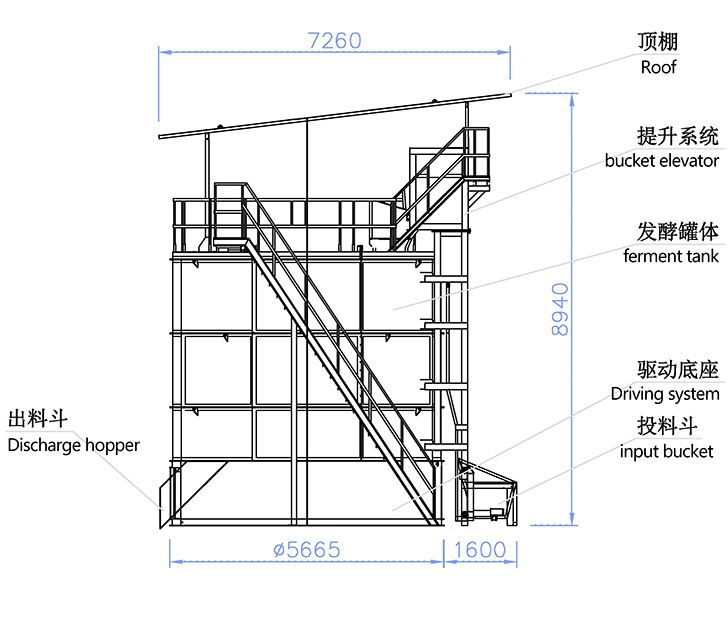

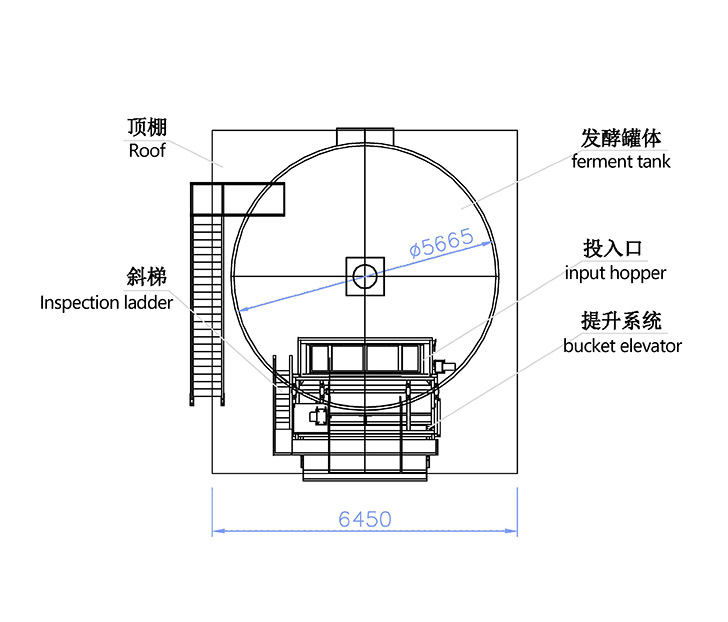

96 m³

Ø5665 mm*8940 mm

32 t

10 t

Approx2 t

13.5 t

Approx5 t

38.53 kw (excluding heating system)

Remarks

Slightly different depending on seasons

Slightly different depending on seasons

24.03 kw (including heating system)

Parameter Name

Volume

Total weight

Electric power

Upper fan

Lower fan

Gear motor

Bucket lifting motor

Exhaust blower

Exhaust fan

Deodorization water pump

Total power (excluding heating system)

Total power (including heating system)

Data

96m³

32t

380V 50hz three-phase

2.2kw

11kw*2tower

7.5kw

0.18kw

2.2kw

3.7kw*2tower

0.75kw

38.53kw

42.53kw

According to the drawings provided by our company, users shall build the equipment installation foundation by themselves.

According to the drawings provided by our company, users shall build the equipment installation foundation by themselves.

Users build organic fertilizer warehouse by themselves

Users build organic fertilizer warehouse by themselves

Connect electric power to the control cabinet of the fermentation tank

Connect electric power to the control cabinet of the fermentation tank

Connect tap water to deodorization system

Connect tap water to deodorization system

Our company is responsible for guiding installation and commissioning of the fermentation tank

Our company is responsible for guiding installation and commissioning of the fermentation tank